The combination of steel and concrete has revolutionised the construction industry. Notable for its high tensile strength, flexibility, and corrosion resistance, adding steel in concrete can make structures sturdier and more durable.

This article delves into the science behind this powerful duo, from their roles in the construction industry to a couple of maintenance tips to ensure longevity. Let’s get started!

The Role of Concrete and Steel in Construction

Adding steel in concrete is common, as they play distinct yet complementary roles in construction. Each possesses unique properties contributing to structures’ overall strength, stability, and durability. Thus, you must understand their parts to create safe, long-lasting buildings and infrastructure.

Concrete: The Backbone of Construction

Concrete is the backbone of construction due to its exceptional compressive strength and versatility. This material comprises cement, aggregates (e.g., sand, gravel, or crushed stone), and water. When these components are combined and allowed to cure, they form a robust and durable material with various applications. Here’s a list of some of its strengths:

- Load-Bearing Capacity. Concrete’s ability to withstand compressive forces makes it ideal for supporting heavy loads, making it the primary material for foundations, columns, and beams.

- Versatility. It can be moulded into various shapes, allowing creative and efficient design solutions.

- Fire Resistance. Concrete is inherently fire-resistant, offering critical protection for buildings and structures.

- Economical. Widely available and cost-effective, concrete is a preferred choice for many construction projects.

However, it’s important to note that concrete has its limitations, including:

- Low Tensile Strength. Concrete lacks tensile strength and may crack or fail under tensile stresses. Steel reinforcement is necessary to counter this weakness. Concrete is also susceptible to shrinkage, which can induce tensile stresses.

- Brittle Behavior. Concrete is quite brittle and prone to sudden failure without warning, especially under dynamic or seismic loads.

- Long Curing Time. Proper curing is essential for strengthening concrete, leading to longer construction schedules.

- Limited Flexibility. Concrete’s rigidity may restrict its use in structures requiring significant flexibility or intricate designs.

Steel: The Mighty Reinforcement

This is where steel comes into play. Adding steel reinforcement like rebars or welded wire mesh in concrete structures can provide them additional strength and ductility. Here are a couple of other benefits it brings:

- Tensile Strength. Steel’s high tensile strength allows it to resist tension forces, preventing cracks and enhancing the overall structural performance.

- Flexibility. Steel’s ductile nature allows it to bend without fracturing, enabling the structure to deform under stress without collapsing.

- Compatibility. Steel posts and concrete exhibit similar thermal expansion rates, ensuring a harmonious relationship between the materials throughout temperature changes.

- Corrosion Resistance. Properly treated steel reinforcement exhibits excellent corrosion resistance, safeguarding the concrete from deterioration.

As you can see, the symbiotic relationship between concrete and steel is crucial in modern construction. By combining them, you can design resilient and safe structures.

Best Types of Steel Reinforcement for Concrete

Choosing the correct type of steel reinforcement is crucial when planning concrete buildings to ensure structural integrity and performance. Here are some of the best options to consider:

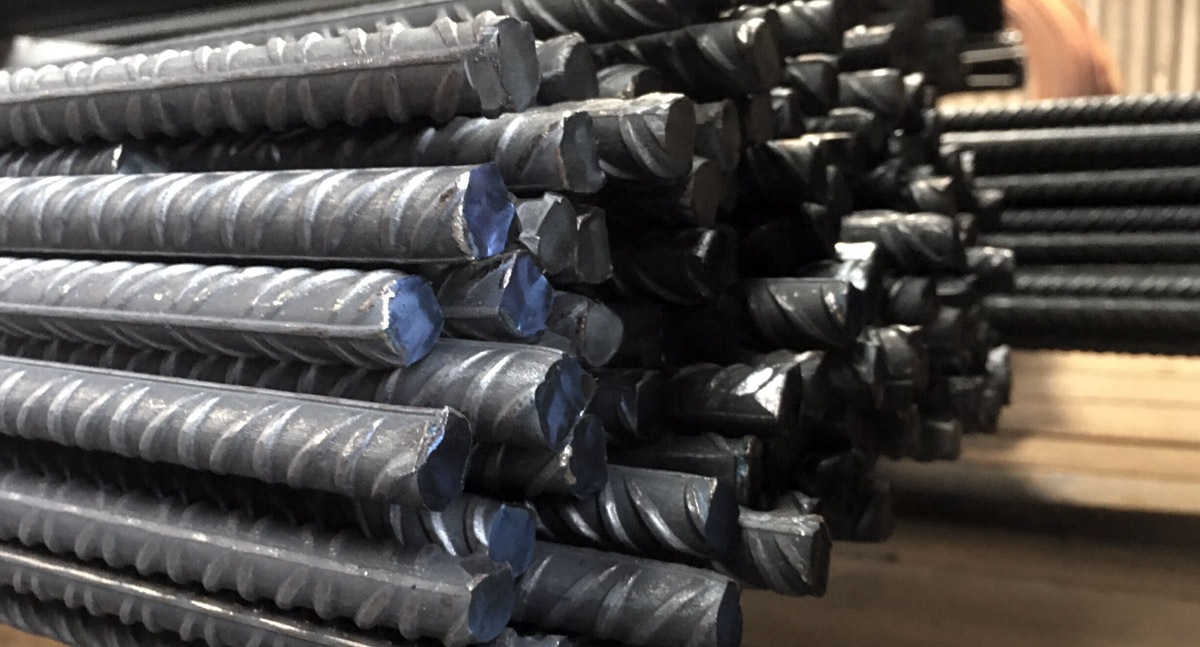

- Deformed Steel Bars (Rebars). Also known as rebars, these are the most widely used type of reinforcement in concrete. These bars have deformations on their surface, providing better adhesion with the concrete, resulting in improved load transfer and enhanced bond strength between the two materials.

- Welded Wire Mesh. Welded wire mesh consists of interconnected steel wires welded together to form a grid pattern. It is a time-efficient option for small to medium-sized concrete projects. The mesh provides uniform reinforcement distribution, reducing the risk of cracking and improving tensile strength. Rectangular meshes are usually the strongest.

- Prestressing Steel. Prestressed concrete is achieved by introducing tension in the steel reinforcement before pouring the concrete. The pre-tensioned or post-tensioned steel helps counteract external loads, creating a structure that can handle higher stress and exhibit better resistance to cracking and deflection.

- Fibre-Reinforced Concrete. In fibre-reinforced concrete (FRC), tiny fibres made of steel, glass, or synthetic materials are added to the concrete mix. FRC offers improved toughness, elasticity, and crack resistance, making it ideal for applications that require enhanced durability and reduced maintenance.

- High-Strength Steel. High-strength steel reinforcement, commonly called HSS, has superior tensile strength compared to standard reinforcing bars. It allows for more slender and lightweight concrete structures, offering cost-saving benefits while maintaining structural integrity.

- Stainless Steel. Stainless steel reinforcement is highly resistant to corrosion, making it suitable for projects in aggressive environments, such as coastal areas or chemical plants. It ensures the longevity and durability of reinforced concrete in harsh conditions.

Factors to Consider When Picking the Right Steel Reinforcement

Selecting the appropriate type of steel reinforcement depends on various factors, including:

- Load Requirements. Determine the expected loads and stresses the concrete structure will bear. Higher loads necessitate more robust reinforcement options.

- Concrete Strength. Consider the compressive strength of the concrete mix. The steel reinforcement should complement the concrete’s strength to achieve a balanced combination of materials.

- Tensile Strength. Evaluate the tensile strength needed to counteract the concrete’s potential cracking and bending stresses. Choose steel reinforcement with adequate tensile capacity.

- Corrosion Resistance. Assess the environmental conditions and exposure to moisture or corrosive agents. Opt for corrosion-resistant steel reinforcement in aggressive environments to prevent degradation and extend the structure’s lifespan.

- Construction Method. Consider the construction method (precast or cast-in-place), as this may influence the type and placement of steel reinforcement.

- Design Codes and Standards. Ensure compliance with relevant Australian or New Zealand steel reinforcement standards to guarantee structural safety and regulatory adherence.

- Project Budget. Balance cost considerations with the desired level of performance. Some types of steel reinforcement may offer better properties but at a higher cost.

- Construction Schedule. Factor in the time needed for fabrication, delivery, and installation of the chosen steel reinforcement, aligning it with the project’s timeline.

- Environmental Impact. Assess the environmental impact of the selected steel reinforcement, considering factors such as embodied carbon and recyclability.

- Special Requirements. For unique projects or applications, consider specialised steel reinforcement options such as stainless steel or fibre-reinforced concrete for improved performance.

- Compatibility with Concrete Mix. Ensure the chosen steel reinforcement is compatible with the specific concrete mix, considering factors like aggregate size and workability.

- Expert Recommendations. Seek input from structural engineers, construction professionals, or steel reinforcement suppliers to gain insights into the most suitable reinforcement options for the project.

Australian Standards When Reinforcing Concrete with Steel

In Australia, there are specific standards for adding steel in concrete structures. By following these regulations, you can better ensure the structural integrity and safety of the construction. The primary standards to remember are:

- AS/NZS 4671: Steel Reinforcing Materials. This standard specifies the requirements for steel reinforcing materials used in concrete construction, including deformed and plain bars, wire, and welded mesh. It covers the mechanical properties, dimensions, and manufacturing tolerances of steel reinforcement.

- AS4672: Steel Prestressing Materials. These standards are crucial for maintaining the integrity and durability of prestressed concrete elements in various construction projects. Part 1 covers general requirements, including material properties, testing methods, and quality control. Part 2 focuses explicitly on high-tensile steel strands and wire used for prestressed concrete, providing specifications and guidelines to ensure suitability, performance, and safety.

- AS 3600: Concrete Structures. AS 3600 provides guidelines for designing and constructing concrete structures in Australia. It includes provisions for using steel reinforcement in concrete members, such as beams, columns, slabs, and footings. The standard covers design principles, material properties, and construction practices.

- AS 2870: Residential Slabs and Footings. AS 2870 is essential for ensuring residential buildings’ structural integrity and stability. This standard provides guidelines and requirements for designing and constructing residential concrete slabs and footings. It covers site classification, soil testing, footing design, concrete slab construction, and moisture protection.

- AS 2327: Composite Structures. This standard outlines the design and construction principles for composite structures, which combine different materials (usually steel and concrete) to create efficient and cost-effective building systems. It covers design considerations, material specifications, and construction practices for composite elements.

- AS 1170: Structural Design Actions (Loading Code). AS 1170 provides guidelines for determining the design loads and actions that various structures may experience during their lifetime. It includes provisions for dead loads, live loads, wind loads, earthquake loads, and other environmental activities that influence structural design.

- AS 1554: Structural Steel Welding – Welding of Reinforcing Steel. This standard focuses on the welding procedures and quality requirements for reinforcing steel used in concrete construction. It ensures the proper welding techniques are followed to achieve reliable and durable welds in reinforcement.

- AS 1100: Technical Drawing. AS 1100 Part 501 sets out the rules and conventions for technical drawings used in engineering, architecture, and construction. It provides uniformity in drawing presentation, including dimensions, symbols, and graphical representations.

- AS 5100: Bridge Design, Part 5 Concrete. AS 5100 Part 5 focuses on designing and constructing concrete bridges in Australia. It includes guidelines for concrete mix design, reinforcement detailing, and other considerations specific to the unique demands of bridge construction.

- AS 3727: Guide to Residential Pavements. This standard guides the design and construction of pavements for residential areas. It covers materials, thickness requirements, and construction practices for driveways, pathways, and other residential pavements to ensure durability and functionality.

Tips to Minimise Corrosion in Steel Reinforcements

Steel reinforcements are widely used in construction due to their exceptional strength. However, they’re still vulnerable to corrosion that can compromise the structural integrity and shorten the lifespan of the infrastructure. Here are tips that can help you prevent or minimise this problem:

- Get Proper Concrete Cover. Ensure adequate concrete cover over the steel reinforcement, as this acts as a protective barrier against environmental elements and corrosive agents.

- Use High-Quality Concrete. Use high-quality concrete with an appropriate mix design and low permeability to minimise the penetration of corrosive substances.

- Ensure Adequate Compaction. Ensure proper concrete compaction during construction to reduce the presence of voids where corrosive agents can penetrate.

- Use Corrosion-Resistant Steel. To enhance corrosion resistance, consider using stainless steel or epoxy-coated reinforcing bars in aggressive environments.

- Avoid Water Ponding. Design drainage systems to prevent water from ponding around the steel reinforcement, as stagnant water can accelerate corrosion.

- Control Cracking. Minimise concrete cracking through proper design, construction techniques, and fibre-reinforced concrete.

- Avoid Chloride Contamination. Limit chloride-containing admixtures and de-icing salts, as chlorides are one of the main culprits in steel corrosion.

- Ensure Proper Curing. Implement appropriate curing methods to promote proper concrete hydration and reduce the risk of early-age cracking.

- Perform Regular Maintenance. Inspect and maintain concrete structures regularly to identify and repair any cracks or damage that may expose the steel reinforcement to corrosive agents.

- Apply Protective Coating. Consider applying protective coatings on the surface of the concrete to provide an additional layer of defence against corrosive substances.

- Get Cathodic Protection. Consider using cathodic protection systems for critical structures or harsh environments to actively prevent steel corrosion.

- Consider Environment and Exposure. Tailor the corrosion prevention strategies based on the specific environmental conditions and exposure of the structure to corrosive agents.

Environmental Considerations When Adding Steel in Concrete

The environmental impact of steel reinforcements can be significant, particularly during their production and end-of-life stages. An International Energy Agency research has noted that iron and steel make up around 68% of the world’s global energy system combustion and industrial process CO2 emissions. Meanwhile, cement and concrete represent 6%. Statista has also observed that US steel concrete reinforcing bar production increased by 2.2 metric tons in 2021.

Thus, it’s essential to consider environmental factors when using steel reinforcement to ensure sustainable and responsible construction practices. Here are some critical tips to keep in mind:

- Reduce Embodied Carbon Footprint. The production of steel reinforcements involves energy-intensive processes, leading to the release of greenhouse gas emissions, primarily carbon dioxide (CO2). Choosing low-carbon or recycled steel can help reduce the embodied carbon footprint.

- Practice Responsible Sourcing. Opt for steel reinforcements from suppliers that adhere to sustainable and responsible sourcing practices. Look for certifications or labels that indicate compliance with environmental standards, for example ACRS Certification.

- Use Recycled Content. Consider using steel reinforcements with a higher percentage of recycled content. Rebar recycling helps reduce the demand for virgin materials and decreases the overall environmental impact.

- Get Corrosion Protection. Adequately protect steel reinforcements from corrosion to extend their lifespan and reduce the need for frequent replacements, thus lowering the overall environmental impact.

- Enforce End-of-Life Recycling. Plan for the end-of-life stage of the concrete structure and ensure that steel reinforcements can be easily separated and recycled at the demolition stage.

- Minimise Waste. Calculate the amount of steel reinforcement required and minimise product wastage during construction.

- Use Sustainable Concrete Mix. Optimise the concrete mix design to use less cement while maintaining structural performance, as cement production significantly contributes to CO2 emissions.

- Perform Life Cycle Assessment. Conduct a life cycle assessment (LCA) to evaluate the overall environmental impact of the reinforced concrete structure, considering all stages from material extraction to end-of-life.

- Consider Alternatives. Explore alternative materials or design solutions offering comparable or enhanced performance with lower environmental impacts.

Tips to Maintain Steel-Reinforced Concrete Structures

Properly taking care of steel-reinforced concrete structures is essential to ensure their longevity, safety, and optimal performance throughout their service life. Here are some of the best tips to follow:

-

- Perform Regular Inspections. Conduct routine visual inspections to identify any signs of cracking, spalling, or corrosion. Early detection allows for timely repairs and prevents issues from escalating.

- Address Cracks Immediately. Promptly repair any cracks in the concrete to prevent the penetration of moisture and corrosive agents into the steel reinforcement.

- Maintain Proper Drainage. Ensure drainage systems are in place and functioning correctly to avoid water accumulation around the structure, which can accelerate corrosion.

- Clean and Remove Debris. Keep the concrete surface clean and debris-free to avoid trapping moisture and potentially causing damage.

- Control Environmental Exposure. Implement protective measures, such as coatings or sealants, to shield the concrete from exposure to corrosive substances, extreme weather, or harmful chemicals.

- Get Corrosion Protection. Again, apply corrosion inhibitors or cathodic protection systems to safeguard the steel reinforcement from corrosion.

- Perform Load Capacity Assessments. Regularly assess the load-carrying capacity of the structure to ensure that it remains within design parameters.

- Monitor Environmental Conditions. Keep track of environmental factors impacting the building, such as temperature fluctuations, humidity, and chemical exposure.

_

- Conduct Non-Destructive Testing. Utilise non-destructive testing techniques, like ultrasonic testing or ground-penetrating radar, to assess the internal condition of the concrete and steel reinforcement without causing damage.

- Follow Manufacturer Recommendations. Adhere to the manufacturer’s guidelines for maintenance, especially for protective coatings or treatments used on the concrete surface.

- Keep Detailed Records. Maintain detailed records of inspections, repairs, and maintenance activities to track the structure’s condition over time.

Should I Put Steel in a Concrete Slab?

Yes, incorporating steel reinforcement in a concrete slab is highly recommended. While concrete is solid under compression, it has weak tensile strength. This means it can crack under tension, which can occur due to various factors such as ground movement, load-bearing, and temperature changes.

Will Steel Rust Inside Concrete?

Yes, steel can rust inside concrete under certain conditions. While the alkaline environment of concrete protects against corrosion, if cracks form in the concrete and allow water and air to reach the steel reinforcement, rust can develop. This process is known as reinforcing steel corrosion or rebar corrosion.

Factors such as chloride ions (commonly found in de-icing salts or seawater) can accelerate this corrosion process. Over time, the rust can expand, causing further cracking and damage to the concrete structure.

Summary

Adding steel in concrete buildings will help guarantee the strength, durability, and safety of your beam, slab, floor and other structures. By following the comprehensive guide above, you’ll gain valuable insights and information into the best practices for reinforcing concrete with steel and maintaining structural integrity over time.